Post about a 3D printing problem — 3D printing problem — online and all the top comments will be: “Is your filament dry?” That is a prudent question to ask, because filament that has absorbed moisture will wreak havoc on print quality and can even cause total print failure.If you want to keep your plastic nice and moisture-free on a budget, then check out Milos Rasic’s element14 project on converting a $10 air fryer into a 3D printer filament dryer.There are plenty of dedicated filament dryers on the market and they aren’t particularly expensive.

But they also aren’t complicated and it is easy to build one with some components from your parts bin and a cheap air fryer from a thrift store.Filament dryers work by heating and circulating air.Some use desiccant to increase passive drying, but the heating process alone is enough to draw moisture out of filament.

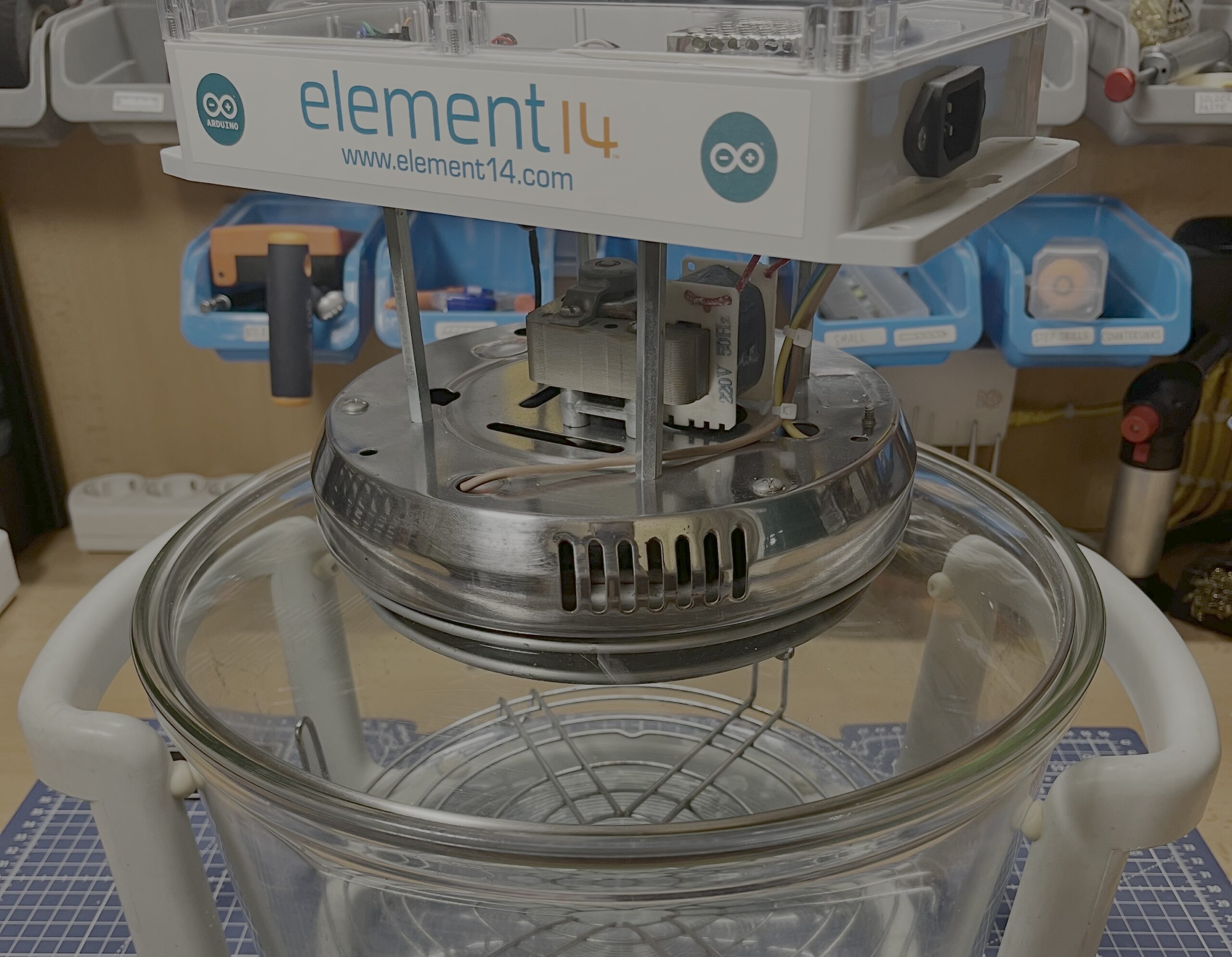

An air fryer already has a heating elements and fans for air circulation, so Rasic just needed to control them with a feedback loop from a temperature sensor.He used an Arduino UNO R4 WiFi board, which controls the 220V fan and heater through a trio of relays: one master relay, one relay for the fan, and one solid-state relay (SSR) for the heating element.The Arduino monitors temperature through a DFRobot DFR0558 temperature sensor. Rasic then built a web-based user interface with the Arduino Cloud, so he can run drying jobs and see status information at any time. One major benefit of this setup is that it can get very hot and will easily exceed 90°C.

Many low-cost filament dryers won’t go over 60°C, so that’s a huge advantage for people working with stubborn filament that is reluctant to release moisture.