3D-printed electronics is an emerging field that combines additive manufacturing techniques with the integration of electronic components to produce previously unachievable results.It enables the creation of complex, customized electronic devices with unique form factors and functionalities.Traditional manufacturing methods often struggle to accommodate the design freedom and complexity offered by 3D printed electronics.

A key challenge is the lack of CAD/CAM tools specifically designed for the unique requirements of additive manufactured electronics.While multi-axis printing adds design freedom, its complexity increases dramatically.These gaps in CAD/CAM software capabilities have limited the adoption of additive manufactured electronics in many industries.

Advanced Printed Electronic Solutions (APES) believes many of these challenges have been solved with the introduction of Aion-5X CAD/CAM software from our company partner KRONOS Mechatronics.Aion-5X is a full CAD/CAM development platform for additive manufactured electronic applications that integrates seamlessly into existing workflows.APES has been working with an early-release version of this new, cutting-edge solution to develop the programs required to drive the Kronos Helios, Hyperion, and APES Matrix6D platforms.

Aion-5X The Aion-5X CAD/CAM solution was developed by KRONOS Mechatronics, a leading company in special-purpose machine building for industrial multi-axis 3D printing systems.Aion-5X is built to meet the needs of additive manufacturing applications, with a focus on printed electronics.It offers a comprehensive set of tools for designing, simulating, and generating five-axis toolpaths for complex printing processes.

The Aion-5X user interface with the preview and the process list.Image courtesy of Advanced Printed Electronic Solutions.The software is designed to work seamlessly with KRONOS’s advanced multi-axis manufacturing platforms and is offered by KRONOS as a proprietary CAD/CAM tool that can be configured for various multi-axis additive manufacturing applications beyond KRONOS systems.

APES has adopted Aion-5X to design and develop 3D-printed electronic applications for its KRONOS Mechatronic platforms and plans to use Aion-5X with its own platforms, including the recently announced multi-scale manufacturing solution Matrix6D.The requirements of multi-axis printing were considered throughout Aion-5X’s development, resulting in a powerful, versatile software platform tailored to additive manufacturing.The software supports the complete workflow from concept to print-ready part, including design, simulation, and toolpath generation.

By incorporating the full kinematic model of the target machine, Aion-5X enables precise visualization and planning of complex multi-axis printing processes.The simulation and the printing process side by side.Image courtesy of Advanced Printed Electronic Solutions.

Users can integrate their own systems and tools through defined, controlled interfaces, enabling them to leverage Aion-5X capabilities, including core software architecture, algorithms, and process logic.At its core, Aion-5X provides advanced multi-axis path planning capabilities that support simultaneous 5-axis printing and generate optimized toolpaths for complex additive manufacturing applications.This enables smooth and accurate printing on challenging geometries and supports high process reliability across a wide range of use cases.

A key feature of Aion-5X is its modular architecture, which allows controlled extension via defined APIs, enabling the integration of additional CAM strategies or external tools where appropriate, while preserving the integrity of the KRONOS core platform.Aion-5X currently supports multiple process strategies.The contour-following strategy enables printing along complex three-dimensional surfaces, while the surface-filling strategy allows larger areas to be filled efficiently with material.

Simulation of the surface filling strategy on a round surface.Image courtesy of Advanced Printed Electronic Solutions.Additional point-dispersion strategies are available for applications such as adhesive dispensing.

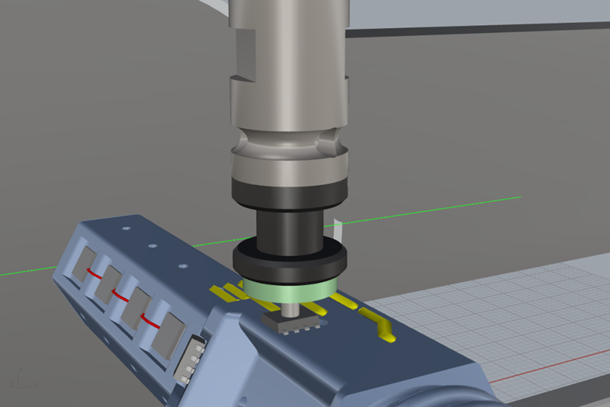

Camera-based component alignment and fiducial recognition support the precise positioning of prefabricated parts within the printing system.Electronic component management and automated pick&place planning are integrated into the software, enabling the production of fully functional electronic devices within a single machine environment.A pick and place operation on the side of the object.

Image courtesy of Advanced Printed Electronic Solutions.Summary and Future Outlook APES continues to see significant advantages in partnering with KRONOS Mechatronics as they continue to evolve the Aion-5X platform with additional capabilities and enhancements, focusing on expanded process support, improved usability, and increased automation in line with future multi-axis additive manufacturing requirements.Crucially, this evolution reinforces the platform’s ability to unify the entire workflow—from design and simulation to final fabrication across multiple machine platforms.

We see no other solution on the horizon that rivals this level of capability and integration.Aion-5X uniquely supports the complete lifecycle of 3D-printed electronic applications, streamlining the process from initial design through to final fabrication.We look forward to our continued partnership with KRONOS Mechatronics to promote this technology and accelerate the adoption of additive manufactured electronics throughout the industry.

About the Author: Rich Neill is CEO of APES, where he leads strategic development and implementation of advanced additive manufacturing technologies for electronic applications.With deep expertise in multi-axis 3D printing and printed electronics workflows, Rich drives innovation that bridges design, simulation, and production across complex manufacturing environments.He is a frequent speaker at industry events and an advocate for expanding the adoption of additive manufactured electronics in both industrial and research sectors.

APES will participate in Additive Manufacturing Strategies (AMS) 2026, a three-day industry event taking place February 24–26 in New York City.On February 26, APES CEO Rich Neill will speak during Session 2: Electronics as part of the panel discussion, “Additively Manufactured Electronics at Scale.” The session will explore the technology landscape, commercialization opportunities, and the future of scaling additively manufactured electronics within the industrial base.AMS brings together industry leaders, policymakers, and innovators from across the global additive manufacturing ecosystem.

Registration is open via the AMS website.Subscribe to Our Email Newsletter Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.Print Services Upload your 3D Models and get them printed quickly and efficiently.

Powered by FacFox Powered by 3D Systems Powered by Craftcloud Powered by Xometry 3DPrinting Business Directory 3DPrinting Business Directory

Read More