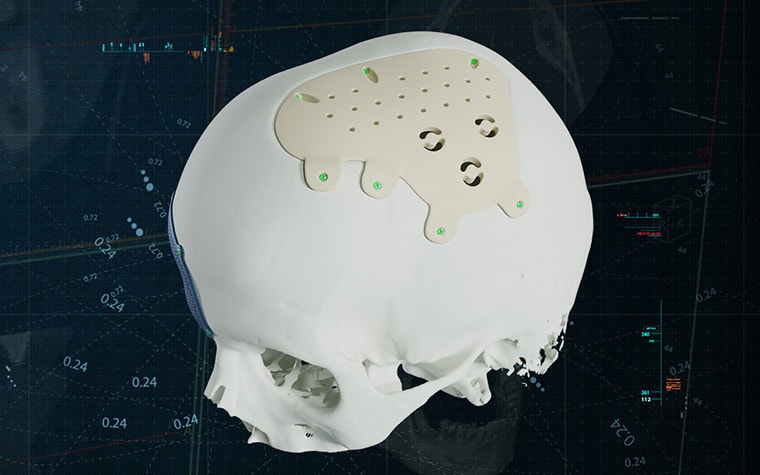

Materialise will implement PEEK (polyetheretherketone), cranio-maxillofacial (CMF) implants.Materialise has been doing CMF implants for decades.SLA and titanium implants, as well as the workflow software to do them, and the software to design them, have been a core part of the Belgian firm’s offering for many years.

The company has also made custom titanium CMF implants, but will now let you order PEEK implants from them through Mimics Enlight CMF.You can also use them with the Mimics Flow case management tool and in Materialise Standard+ Solutions.Maarten Zandbergen, Market Manager at Materialise, noted, “Personalization isn’t just about material choices but about the precision of the planning process and the reliability of execution.

Our clinical engineers work hand in hand with surgeons to design each implant, and that collaborative approach remains constant whether the case calls for titanium or PEEK.What changes is the surgeon’s freedom to choose; what stays the same is the peace of mind that comes from a proven, end-to-end process.” The company expects this to be especially useful in “cranial reconstruction, as well as facial contour restoration and onlay applications,” with specific advantages being “artifact-free postoperative imaging to lightweight anatomical restoration.” Rather surprisingly, the implants are not manufactured in Leuven or other Materialise sites. These PEEK components will be made by Ad Mirabiles, a Swiss-based firm that specializes in manufacturing custom PEEK and titanium implants.The company has EN ISO 13485 and can manufacture within 72 hours.

This is a great step forward for Materialise.PEEK implants are functional and in demand worldwide.For custom work, they have shown efficacy and are often liked by surgeons.

PEEK and other PAEK materials are radiolucent, making it easy for surgical teams to review images after the fact.Designed correctly, they have less stress shearing due to the modulus being close to that of bone, while being very strong and biocompatible.Previously, Materialise would have wanted to do the printing itself.

With Victrex keeping the medical PEEK powders to itself and the recyclability of PEEK still atrociously low, the economics of PEEK LPBF are terrible.Ad Mirables seems to be using Material Extrusion.They may have developed a novel capability in making implants in a certain way.

Materialise also has extensive experience in material extrusion across regulated industries.It could have opted for a 3D Systems EXT 220 MED instead.Printing with PEEK.

Image courtesy of Materialise.So what is Materialise as a platform? Is it the previous three-pillar firm where medical, software, and services strengthen each other? Or is it a workflow platform that offers solutions to people who need parts and other services? Or is the firm the connective tissue around innovation and design of novel products? Or is it a little bit of all of these things? PEEK and PAEK materials are definite opportunities for Materialise.Beyond being a trusted end-to-end platform that takes work away from doctors and gives them and their patients the parts they need, it presents a significant opportunity.

But selling software and providing parts can be very different businesses.It will be interesting to see which way Materialise will lean over the coming years.Will the firm become more of a platform or stay true to its roots? Subscribe to Our Email Newsletter Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Print Services Upload your 3D Models and get them printed quickly and efficiently.Powered by FacFox Powered by 3D Systems Powered by Craftcloud Powered by Xometry 3DPrinting Business Directory 3DPrinting Business Directory

Read More