I recently posted about how the acting commander of the U.S.Army Materiel Command (AMC), Lt.Gen.

Christopher Mohan, told interviewers at the Association of the U.S.Army (AUSA) Annual Meeting that the Army is planning to step up its use of additive manufacturing (AM) for repairs.As I noted in that post, Mohan echoed a series of recent comments made by Secretary of the Army Dan Driscoll concerning the branch’s urgent need to ramp up its use of 3D printing for maintenance, repair, and operations (MRO).

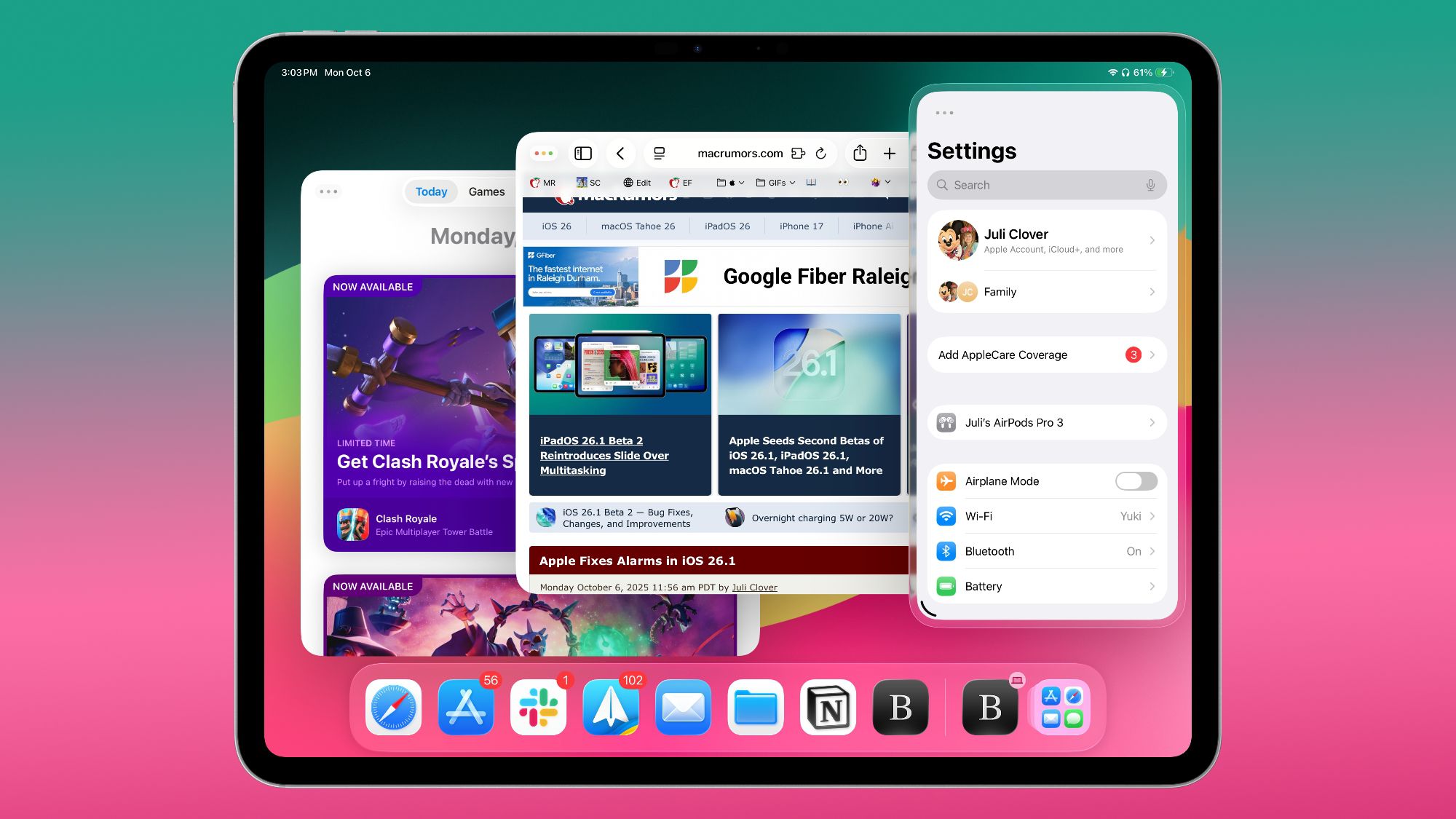

At last week’s AFCEA TechNet Indo-Pacific 2025 conference, Army officials continued to push listeners’ attention to what the branch is doing with AM, specifically for organic drone production.Breaking Defense reports that, during a presentation at the conference, Capt.David Velasquez, a commander in Hawaii’s 25th Infantry Division (ID), told the audience that the 25th had recently 3D printed a first-person view (FPV) drone with lethal capabilities.

A U.S.Army Soldier assigned to the 25th Infantry Division builds a drone in a First-Person View (FPV) Drone Operating Course on Schofield Barracks, Hawaii, July 24, 2025.Image courtesy of U.S.

Army Spc.Wyatt Moore, 28th Public Affairs Detachment, via Breaking Defense.This is a first for the division, and to my knowledge, it is also the first time that the U.S.

military has publicly disclosed such activity: ”Our Lightning Labs team has fabricated a drone that we’re calling the Capstone drone, and in partnership with the EOD [explosive ordnance disposal] team, they’ve developed a detonation system for that drone so that we can go ahead and put lethal effects on target,” Velasquez said.“[It’s] completely built in house here in the 25th ID, so [I’m] extremely grateful to the soldiers who are extremely motivated.They want to get out here and be proficient on their systems, and they really do work.

They can put lethal effects on target right now.” Given the purpose of the conference, which focuses specifically on national security issues in the Indo-Pacific Command (INDOPACOM) region, Velasquez’s comments were contextualized above all within a framework of AM’s significance to the U.S.military’s presence in INDOPACOM.As a description on the Department of War (DoW) website notes, “The United States Indo-Pacific Command (USINDOPACOM) Area of Responsibility (AOR) encompasses about half the earth’s surface, stretching from the waters off the west coast of the U.S.

to the western border of India, and from Antarctica to the North Pole.” It is both the oldest and largest combatant command in the DoW.In the same article, Breaking Defense also detailed similar comments that General Ronald Clark, commanding general of Army Pacific, made about AM’s special importance to INDOPACOM issues during his keynote address: “When we think about the Indo-Pacific, we envision vast and diverse terrain, from dense jungles to coral atolls, from frozen Arctic tundra to tropical archipelagoes, from coastal plains to the most majestic and massive mountain ranges on the planet.” According to Clark, the “vast and diverse terrain” comes with logistical challenges that require AM to be addressed.I briefly mentioned the 25th ID in a post from September about the Oregon Army National Guard’s use of 3D printing as a central pillar in a new drone training curriculum that aims to drastically reduce the cost of small drones, among other objectives.

Work by the 25th ID was one of the main sources of inspiration for the program in Oregon.Staff Sgt.First Class Gregory Mannen operates an RQ-28A Sky Ranger drone during training at Rees Training Center, Oregon.

Images courtesy of Major Wayne Clyne, Oregon National Guard Public Affairs Office.In that vein, one can presumably expect that the other capabilities that the 25th ID develops will, soon enough, also make their way to other locales within the U.S.military.

The more complex — and more lethal — that these capabilities get, the more I think we can expect cybersecurity to move to the forefront of the DoW’s concerns when it comes to AM.For some time, I’ve found it incongruous that mainstream media sources express such dismay about 3D printed guns when 3D printed drones already exist.While the 25th ID worked with a designated ordnance team to make its FPV drone lethal, the war in Ukraine — the laboratory that the vast majority of these ideas originate in — has amply proven that you don’t need anything all that sophisticated to weaponize a drone.

For instance, back in June, a story in Defense News described how in early 2024, a Ukrainian soldier fashioned a working bomb out of plastic explosive and a Pringles can, then attached the bomb to a low-cost DJI drone.Meanwhile, in September, President Trump told a gathering of U.S.generals that American cities should be used as “training grounds” for the armed forces to fight the “enemy from within.” I question very much the validity of that sentiment.

But, if that is going to happen, and if National Guardsmen are quickly gaining the capabilities to 3D print objects that can be easily weaponized, the bare minimum of rational behavior would be to not only ensure that the highest cybersecurity standards are in place, but the individuals being trained in these capabilities also need to be vetted as stringently as possible.Granted, at this point, it is utopian to expect adherence to any sort of bare minimum of rational behavior.But as society’s general footing continues to descend into madness, it doesn’t seem unreasonable to think that a counterbalance of good sense could eventually start to emerge.

Featured image: U.S.Army Soldiers from the 25th Infantry Division use a Developmental Command Exportable Lab to assemble first-person view drones for use during Joint Pacific Multinational Readiness Center-Exportable at Fort Magsaysay, Philippines, on May 24, 2025.The capability enabled the deployment of more than 100 FPV drones during this rotation.

Photo by 1st Lt.Aylin Hernandez, 25th Infantry Division, via DefenseScoop.Subscribe to Our Email Newsletter Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Print Services

Upload your 3D Models and get them printed quickly and efficiently.Powered by FacFox

Powered by 3D Systems

Powered by Craftcloud

Powered by Endeavor 3D

Powered by Xometry

3DPrinting Business Directory

3DPrinting Business Directory