Sugino Machine Ltd has recently completed development of a highly specialized surface-finishing technology capable of removing partially melted particles, debris, and alpha case left behind by additive-manufactured (AM) laser powder bed fusion (LPBF) of titanium alloys such as 6Al-4V.Cavitation abrasive surface finishing and peening (CASF) goes beyond line-of-sight processing methods such as tumbling or grit blasting, since the powerful shock-wave action occurs wherever the imploding water-cavitation vapor bubbles can be directed to enter and activate.Because of this unique omnidirectional capability, CASF can treat very long circuitous internal passageways, as well as the walls of drilled holes, bores, cornices, cut tunnels, tubular channels, return flanges, overhangs, and other deep trapped chasms.

CASF was derived through high-speed camera studies of the water cavitation effect created by the powerful club that is used as a weapon by the Mantis Shrimp.Cavitation water jet peening was originally derived from high-speed imaging studies of the highly evolved Mantis Shrimp, whose specialized club generates an energetic cavitating cloud in seawater as it accelerates at a rate equal to that of a bullet fired from a gun.When the Mantis’s punch wave blast strikes the outer shell of its prey, the result is instant obliteration, and that allows the creature easy access to the delicious meal that it craves.

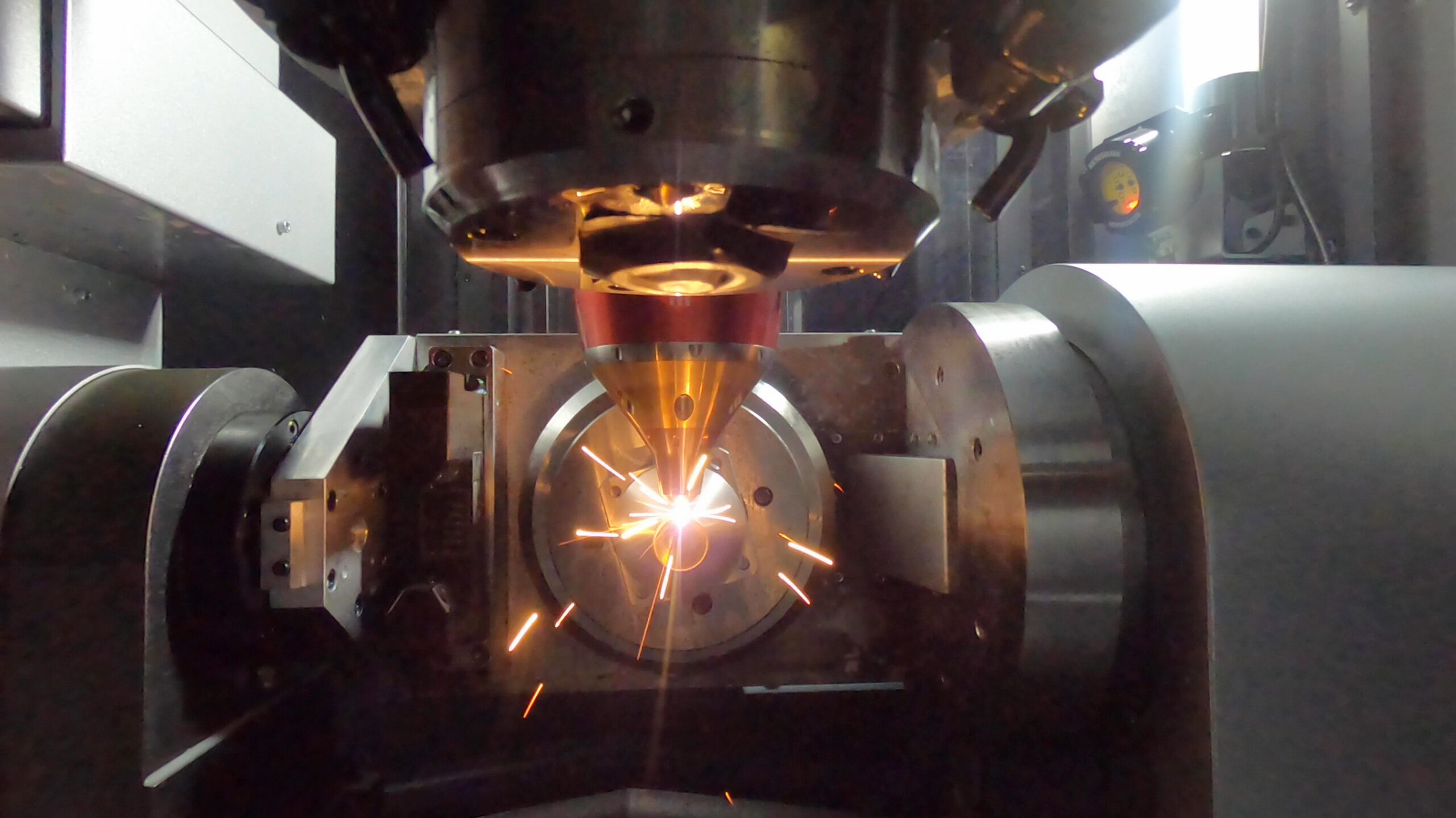

Cavitation abrasive surface finishing and peening (CASF) is created by shock waves that are generated by a nozzle acting through a slurry of water and abrasives upon a workpiece.Sugino’s CASF process is conducted inside a fully automated CNC machine that contains a fluid chamber holding an agitated slurry mixture of water and abrasives.The commercially available cutting media types used are environmentally benign ceramics, such as garnet or alumina.

Inside the processing tank, the slurry is energized by a cloud of thousands of tiny water cavitation vapor bubbles, which violently implode as they undergo a phase transformation from vapor back to liquid.The wave action created by cavitation also kinetically energizes the abrasive particles – giving them motion and ballistic power.The abrasives’ sanding action slices and blows off the partially melted AM particles very quickly.

As the clean, bare metal is exposed, the water constituent of the slurry strikes the surface, imparting compressive residual stresses.Wave action has similar results to shot peening, but at the molecular scale of water (H2O), with a 1.7 Angstrom size vs.the typical shot peening media diameter of ~1 mm +/- ½ mm, and molecular water about 1/10,000,000th the size of shot media for comparison.

CASF does not leave behind the crater-like impressions associated with shot peening, and because metal is not displaced to the same degree, dimensional distortion of AM parts is virtually eliminated.The inside of tubular AM LPBF Ti 6Al-4V test samples built with various diameters, necks, and angles of attack were treated with CASF.Recent testing conducted on AM LPBF titanium 6Al-4V tubular parts with partner universities and industrial partners has shown that CASF will yield an internal and external surface roughness average Ra around 3-4 um, when starting from Ra 10-26 um hot isostatic pressed (HIP) test samples.

Various additional prototype parts representative of production hardware have also been successfully processed.The CASF method has been shown to work equally well on other alloys, such as Inconel, stainless steel (CRES), high-carbon steels, and aluminum.AM surface quality varies on as-built parts due to the effect that gravity has during the solidification of melted particles.

Compressive stresses, beneficial for avoiding the initiation of fatigue crack starts, have been observed to be in a range of -300 to -550 MPa when starting from nearly 0 MPa up to +250 MPa, even when measured at points that are deep inside trapped areas.Fatigue test data show significant cyclical life improvements when CASF is compared to as-built and HIP, and it is approaching parity with surfaces finished with conventional methods such as sanding, machining, and chemical milling using legacy substances.One of the fundamental challenges associated with AM has been post-process finishing, which can involve the extensive use of not-quite-effective automated abrasive machines, line-of-sight grit blasting, micro-machining, hand working (repetitive motion) methods, and/or the use of toxic synthetic mixtures such as nitric hydrofluoric acid or etchant solutions for post-printing surface finishing.

CASF is completely benign and is a green alternative to using harmful chemicals.The slurry used by CASF is non-toxic, is safe for direct human contact, and does not require the care and disposal of industrial waste.Process water is filtered and recirculated within the machine.

A clear-water spray and hot-air drying are all that are required for post-CASF cleaning of AM parts.Sugino is currently seeking collaborative opportunities within the AM industry to test hardware and parts and demonstrate the capabilities of CASF as an alternative to conventional methods.About the Author: Dr.

Daniel G.Sanders is Vice President of Research and Technology at Sugino Machine Ltd.and an Affiliate Professor of Mechanical Engineering at the University of Washington.

His work focuses on advanced manufacturing processes, surface finishing technologies, and the mechanical performance of engineered materials, with particular emphasis on applications in additive manufacturing and high-performance metal components.Sugino Machine Ltd.is a Silver Sponsor of Additive Manufacturing Strategies (AMS) 2026, which will take place February 24–26 in New York City.

AMS brings together industry leaders, policymakers, and innovators from across the global additive manufacturing ecosystem.Registration is now open.Images courtesy of Sugino Subscribe to Our Email Newsletter Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Print Services Upload your 3D Models and get them printed quickly and efficiently.Powered by FacFox Powered by 3D Systems Powered by Craftcloud Powered by Xometry 3DPrinting Business Directory 3DPrinting Business Directory

Read More