When Foster Ferguson joined Stratasys after a long career in the U.S.Marine Corps, he brought with him a logistics mindset: every mission succeeds or fails on readiness.That same principle now guides his work as Vice President of Industrial Business at Stratasys, where he’s helping push additive manufacturing (AM) deeper into aerospace, defense, and beyond.

In a conversation with 3DPrint.com, Ferguson described how 3D printing is transforming aerospace manufacturing, from drones and defense spares to tooling and materials built for space.“There’s a big demand right now for drones and UsX (unmanned systems) to address challenges on the battlefield,” he said.“That’s been driven by conflicts like Ukraine and a wider shift in how militaries think about tactics and strategy.” From the Marines to Manufacturing Ferguson’s years in military logistics left a clear mark on his leadership style: “In the military, you learn that you don’t have to be the smartest person in the room.

You just need smart people around you.And at Stratasys, that’s what we’ve built.” Foster Ferguson.Image courtesy of Stratasys.

He leads teams of engineers and business experts who approach problems the same way he once handled supply chains: fact-based, practical, and focused on results.“Something has to start here and appear over there.That’s a fact-based problem,” Ferguson said.

“We try to solve it with fact-based solutions.In logistics, everything comes down to movement — you can’t rely on theory or assumptions.You have to see results.

We try to deliver that same mindset to manufacturing support: define the problem, find the right people, and deliver a solution that works in practice, not just on paper.” That approach defines Stratasys’s work with industries where precision and reliability matter most, like aerospace, automotive, and defense.“Supporting organizations like the U.S.Navy, Air Force, or Marine Corps means you have to deliver complete capabilities, not just single products.

And we welcome that—it makes us better.” Building for the Skies—and Beyond To Ferguson, few sectors illustrate the transformation of AM as clearly as aerospace.He describes three areas where Stratasys is most active: the commercialization of space, unmanned systems, and defense spares.In space, Stratasys has been working with companies like Lockheed Martin, Northrop Grumman, Blue Origin, and SpaceX on materials tailored for extreme conditions.

One of the most promising is Antero 840CN03, a high-performance thermoplastic with electrostatic-dissipative properties, which is essential for spacecraft where stray static can cause failure.“You don’t want static in space.That material, known as Antero 840CN03, has an electrostatic-dissipative component that makes it ideal for spacecraft and satellite applications.

We’ve been working closely with aerospace primes to qualify these materials for flight, conducting extensive testing with the Department of Defense and multiple OEM sites.We wanted realistic data, from site to site, printer to printer,” he said.“Now, when you have a qualified process, you can produce parts approved by the FAA [Federal Aviation Administration].

That’s a huge deal.” Antero 840CN03 PEKK.Drones and the Additive Advantage “If space represents the long horizon of additive manufacturing, unmanned aerial systems show their rapid-fire side,” stated Ferguson.In central Texas, home to unexpected clusters of drone innovation, Stratasys is collaborating with both large and small manufacturers, developing the next generation of military and commercial platforms.

“We’re involved with large-scale drone programs and smaller, more disposable systems.Additive is perfect here because you can rapidly iterate, test, and redesign on the fly.” For drones, speed of development can be as critical as the flight itself.“When you’re testing your platform, you can change designs while creating the controls.

You compress the whole process, with no need to source parts or wait on tooling.” Larger defense platforms use Stratasys’s FDM-based high-performance thermoplastics like ULTEM 9085 or Antero 800NA, which combine strength and heat resistance.Smaller drones, especially those meant for single-use missions, benefit from powder-based technologies, where parts can be produced cheaply in batches.“For smaller drones, you’re not designing for decades of use, you’re designing for speed and scale,” Ferguson explained.

“We print those using our powder-based technology, where the focus is on cost per part.‘Let’s keep it under twenty dollars,’ that’s the kind of thinking in that space.” SAF Drone.Drones are also opening the door for new entrants to the aerospace industry.

Because they don’t carry passengers, the certification burden is lower than in traditional aviation, giving manufacturers more freedom to experiment.That’s why unmanned systems are such a great entry point for additive, Ferguson adds.Readiness Through 3D Printing One of Ferguson’s main priorities is defense spare parts, which are the pieces needed to keep older military equipment running.

Many platforms still in service are 30 or 40 years old, and sourcing parts for them can be incredibly slow.“Some contracts are written so that a supplier won’t even start production until demand hits a hundred units.If that supplier disappears, you’re stuck.

Why not just repair the part yourself with additive?” He sees 3D printing as a way to restore self-reliance.“It’s about the right to repair—to get equipment back into circulation quickly and keep it ready.That’s what readiness really means.” He believes the same idea could work in other industries like oil and gas or automotive, where supply chains are often under pressure.

“We don’t need to overthink it,” he added.“We’ve been machining for hundreds of years, so why not treat additive the same way?” Crossing the Chasm According to Ferguson, additive manufacturing in aerospace has reached what he calls an inflection point.“We’ve crossed from early adopters to early majority,” he said.

“The companies we work with aren’t just kicking the tires anymore; they’re integrating additive into real production.And that shift requires three ingredients: adoption, reliability, and confidence.Adoption occurs through standards and qualifications.

Reliability means uptime, where the printer consistently performs, and confidence comes from repeatability, which ensures that each part matches the last.When those three come together, you can integrate additive into manufacturing for real.” U.S.Air Force Senior Airman Abram Reyes checks maintenance parts of the 31st MXS metals shop Stratasys F900 3D printer at Aviano Air Base, Italy, in 2024.

Image courtesy of U.S.Air Force photo by Staff Sgt.Heather Ley.

Beyond aerospace and defense, Ferguson is equally excited about the automotive side of the business.Stratasys recently opened a North American Tooling Center in Flint, Michigan, dedicated to helping automakers develop production-ready tooling.“When you’re making a truck every 57 seconds, the line isn’t the place for experiments,” he said.

“Tooling with additive lets us test, refine, and deploy faster.If you’re not using additive for tooling, you’re already behind.” That same focus on tooling is showing up across the industry.Earlier this month, AM Research, in collaboration with Stratasys, released a white paper on the next generation of 3D printed tooling and its role in reshaping production workflows.

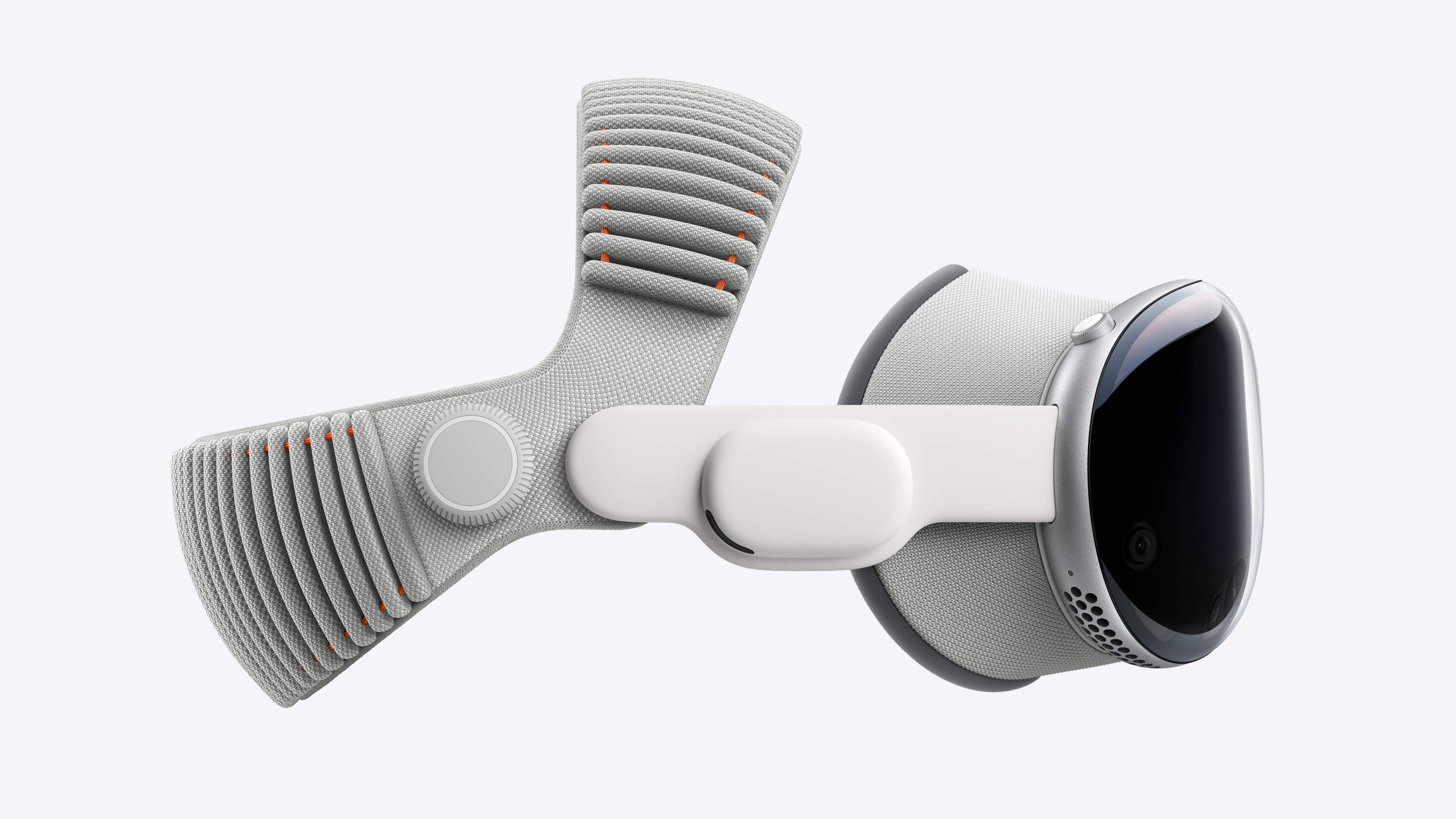

A follow-up webinar on October 16 will further explore these findings, and highlight how manufacturers are turning tooling into one of additive’s biggest opportunities.Military drone camera housing.Looking ahead, Ferguson sees opportunity in automation and robotics, sectors that “pair like wine and cheese” with AM.

And even as the industry consolidates, he’s confident Stratasys will keep leading by example: “We listen to our customers.They give us the answers to the test,” concludes Ferguson.Images courtesy of Stratasys unless otherwise noted.

Subscribe to Our Email Newsletter

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.Print Services

Upload your 3D Models and get them printed quickly and efficiently.Powered by FacFox

Powered by 3D Systems

Powered by Craftcloud

Powered by Endeavor 3D

Powered by Xometry

3DPrinting Business Directory

3DPrinting Business Directory