If you need to move fluid from one vessel to another, you’re probably going to want a pump of some kind.Typical inexpensive pumps are usually only on or off, so you can’t easily control the flow rate.Those that do have some kind of analog adjustment are usually imprecise, which is a problem in lab settings.

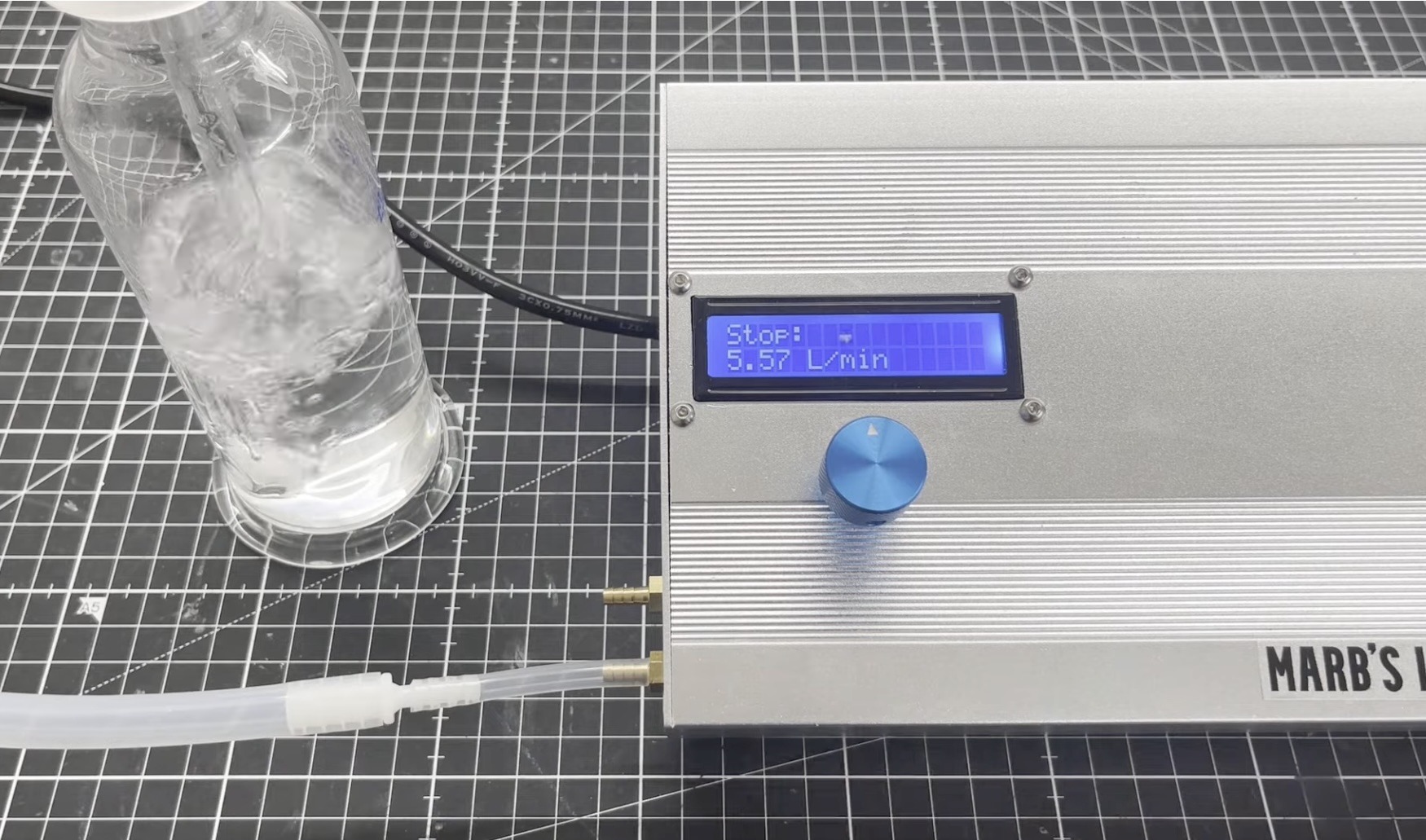

To solve that problem on a budget, Marb designed a DIY programmable diaphragm pump unit. The pump Marb used for this project is just a 12VDC diaphragm pump that you can get anywhere for a few dollars.It only has two leads: positive and negative power.Connect those to a DC power source and the pump will run at a constant rate.

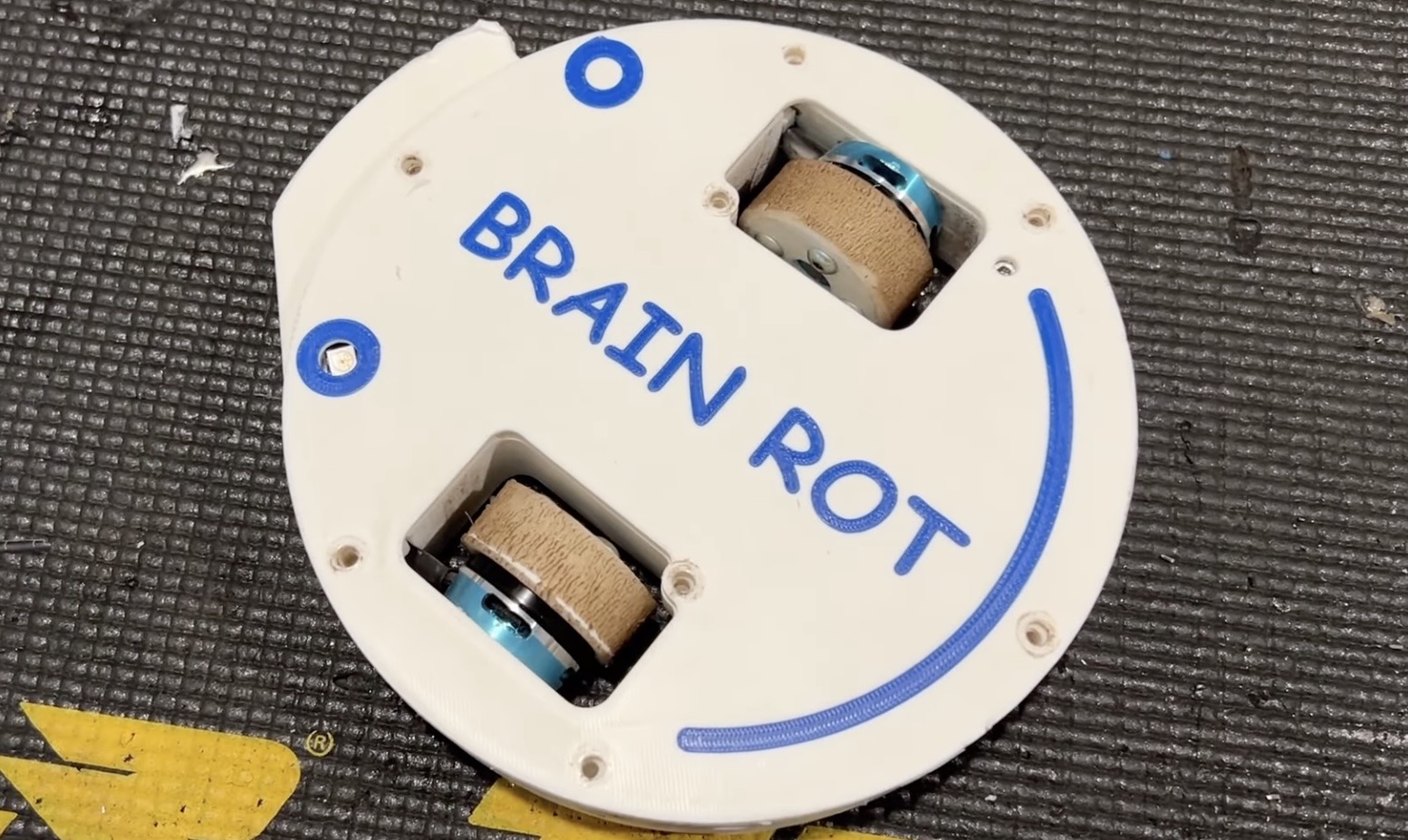

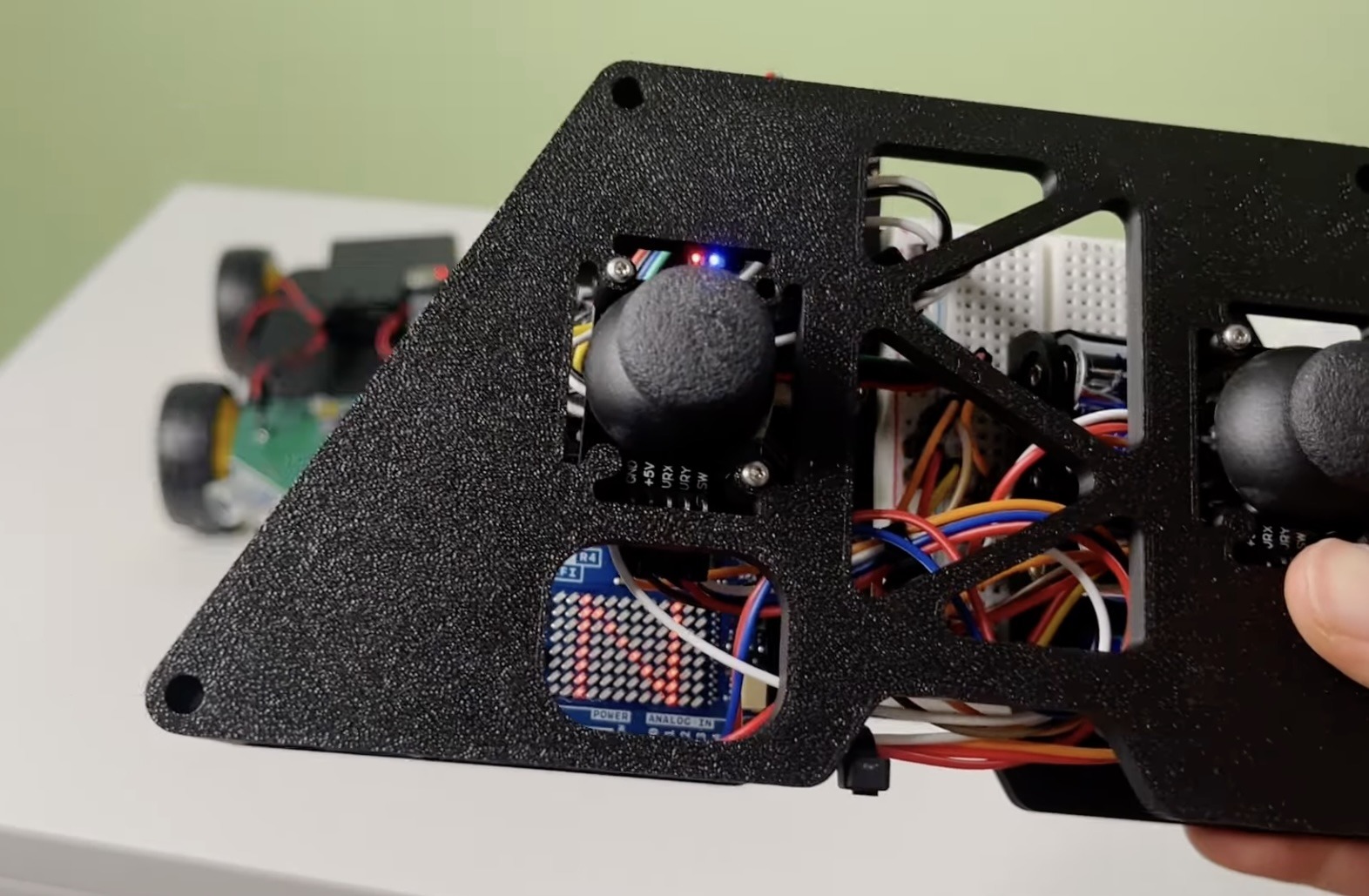

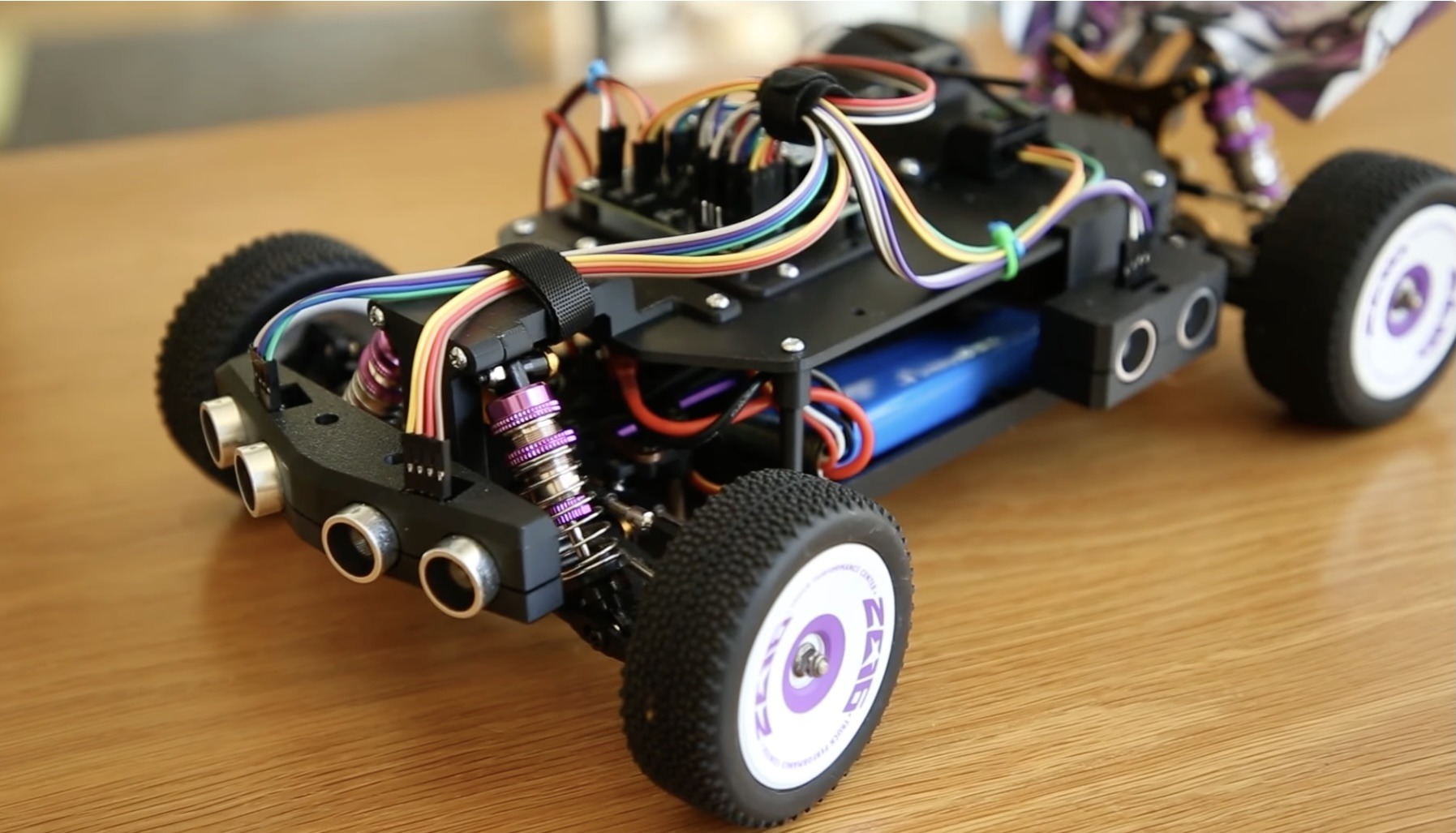

The other electronic components that Marb added, all of which fit inside a nice aluminum enclosure, let the user set a flow rate with much better precision than you would get through some form of analog control.This works by adjusting the effective average voltage to the diaphragm pump’s electric motor through pulse width modulation (PWM).In this case, an Arduino Nano board tells a power MOSFET module (intended for 3D printer heat beds) to switch on and off very quickly.

The ratio of “off” to “on” determines the average voltage and therefore the pump motor’s speed and ultimately the flow rate.The user can set that speed by telling the Arduino what PWM value to use.They do that through a simple interface consisting of a 16×2 character LCD and a KY-040 rotary encoder. It will take some calibration to find out the real-world flow rates that correspond to the PWM values.

But afterwards, this should be precise and accurate enough for many tasks in the lab.