CAD and 3D printing veteran Carl Bass is to leave Formlabs‘ board after eight years.Formlabs Board Chairman Natan Linder said, “Formlabs also announced that Carl Bass will step down from the Board following more than eight years of dedicated service.Bass joined the Formlabs Board in 2017 and has played a significant role in helping the company redefine additive manufacturing.

Carl has been an extraordinary partner to Formlabs.He brought strategic clarity, bold ambition, and deep empathy for builders and designers.We’re deeply grateful for his leadership and the lasting impact he has made on the company.” The former Autodesk CEO will be replaced by Rob Willett.

Rob Willett is the former CEO of the Cognex Corporation, a machine vision company with $875 million in revenue that makes tools for semiconductor manufacturing, barcode scanning, OCR, and defect detection.Formlabs premium teeth resin.Image courtesy of Formlabs.

Machine vision is an adjacent industry to 3D printing, and on desktop Material Extrusion, we can see that machine vision has helped usher in a revolution.Machine vision is used for more accurate extrusion, deposition, and intra-layer bonding.Perhaps Formlabs could use some of that to improve its own printers.

More probably, however, they’re looking for executive guidance and experience to bolster growth and a possible IPO.Rob Willett.Image courtesy of Cognex.

Willet says that, “Formlabs has built an industry-leading platform at the intersection of manufacturing hardware, software, and materials,The company is uniquely positioned to drive the next era of digital production by making powerful fabrication tools more accessible without sacrificing performance.I’m excited to join the Board of Directors and help guide the company as it continues to scale globally.” Formlabs Board Chairman Natan Linder believes that, “Rob has built and scaled global industrial technology businesses with operational rigor and discipline, There is a strong MIT-rooted heritage connecting Cognex and Formlabs, two companies built at the intersection of software, hardware, and manufacturing.As Formlabs continues its evolution from breakthrough startup to enduring manufacturing platform, his experience scaling complex hardware and automation companies will be invaluable.” Formlabs is evolving.

The company was once a one-technology, essentially one-integrated-product company centered on founder Max Lobovsky.Now with many more materials, printers for specific applications, sintering, and more complexity overall, the firm is becoming larger and more complex.It has many more products to support, many more interactions and dependencies, more departments, and more people to manage.

The more complex beast is still formidable.It puts out an excellent series of products that work well.Sintering systems have teething problems but are now showing maturity.

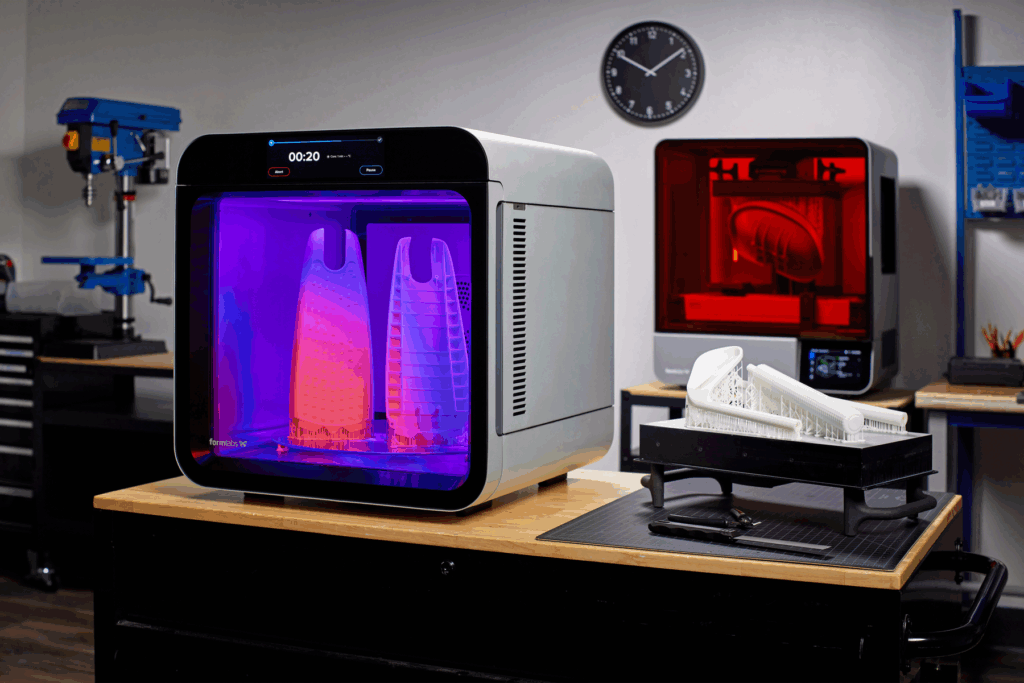

The SLA systems have always been good and have improved, getting much bigger and more sophisticated.Formlabs is now faced with a choice to specialize in more sectors within SLA and sintering and make more application-specific solutions, or to expand in other ways.Expanding in other ways could be a choice to ship more automation, workflow, and organizational software, becoming the software partner for many manufacturing businesses.

This is less strange than it sounds.Many of its clients only run CAD and Formlabs software, while many others have lots of different 3D printers from different brands and a balkanized mess of other PLM and other packages.Other clients are small and want something specific for a two-person team or a design-led lamp company with five employees.

There is no real good solution for these people, and definitely not a good, inexpensive solution.Pivoting to become the connective tissue for manufacturing firms would be a strong move.Formlabs booth at MILAM 2026.

Image courtesy of 3DPrint.com.Another play would be to develop desktop CNC, milling, and laser-cutting devices.These devices could gain ready commercial appeal and significantly broaden the firm’s offering.

I’d probably advocate for a hybrid of both solutions.On the one hand, introduce a desktop water jet or similar while expanding the software to act like an MES, PLM, and print farm manager for Formlabs and other equipment.This seems like a logical extension of current capabilities, while serving customers it now has long-term relationships with.

Either way, the big discussion in the boardroom is whether, in this current rollercoaster economy, going public is a desire or a need.This looks like an opportune appointment and a continuation of Formlabs’ march toward growth and perhaps an IPO.Subscribe to Our Email Newsletter Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Print Services Upload your 3D Models and get them printed quickly and efficiently.Powered by FacFox Powered by 3D Systems Powered by Craftcloud Powered by Xometry 3DPrinting Business Directory 3DPrinting Business Directory

Read More