Back in 2013, I remember being completely blown away when a company called Solid Concepts reportedly additively manufactured nearly a complete firearm as a proof of concept.Although desktop polymer 3D printers had already been making headlines around the possibility of illegal manufacturing of unserialized “firearms” (which really resembled more of an explosive device powered by traditional small arms cartridges), this was the first time a legitimate contract manufacturer had applied metal additive manufacturing to make an actual serialized, legal firearm.As far as can be remembered, they produced most of the actual components via AM as a proof of concept, but certainly other manufacturing processes were involved as they would always need to be in producing an enthusiast-quality firearm.

Recently, coming home from the SHOT Show in Las Vegas—one of the biggest global small arms and shooting sports shows in the entire world—it is remarkable to look at where the additive industry has come in this space.There were easily two dozen additive manufacturing-related companies in the show’s Supplier Showcase this year, the most I can ever recall seeing.And this is no surprise, given the last eighteen months of innovation and explosive growth in the area of small arms silencers—essentially what is a muffler for a firearm.

And while yes, there was a cross section display sample of a 3D printed metal suppressor on basically every AM company’s tabletop in this area of the show, there’s actually a lot more to the adoption of powder metal manufacturing tech in this space that AM stakeholders might want to take note of.Applications, Materials, Processes, and Business Model Innovations Even though I’ve just said there’s more than just silencers to pay attention to in the world of small arms, I should start off by being clear in this area.Small arms silencers will be to metal powder AM technologies what the dental and jewelry industries combined are to photopolymer AM technologies.

I’m not just talking about selling some printers, but about moving the dynamics of the entire metal powder industry.This application is impacting additive in a similar fashion to the way that rocket engines did the last four years or so.Silencers made via metal additive are the entry point for many.

However, the SHOT Show this year highlighted the idea that there are also more applications to explore in the area of small arms.It’s notable to point out the adoption of another non-additive metal forming process, which still is technically the king of the world of small arms: metal injection molding (MIM).In the world of MIM, firearms are one of three clear industry-leading applications across the globe.

Why do we, the additive industry, care about MIM’s role in small arms? First, we can get some idea of the possible application map for additive technologies in this space beyond silencers.Smaller, less geometrically complex parts for firearms (such as release levers, muzzle breaks, locking pins, etc) aren’t always the first thought for AM.However, in the area of small arms, custom and low volume/high value have become a significant driver of the boutique side of the industry.

Combined with AM’s rapid ability to fabricate with materials like titanium or stainless steel alike, we can see how MIM has provided the blueprints for AM to play off of—not necessarily for significant volumes of the same parts, but for smaller volumes and a high mix of custom parts.New applications for both MIM and AM are also emerging in the space and were on display at SHOT Show.Magpul’s booth showed MIM knife tangs and blades, making for an impressive showcase of the technology.

Meanwhile, AM is simultaneously being explored for direct printing of an entire knife assembly including metallic grips and blades, something which was shown by One Click Metal at formnext 2025 a few months ago.But maybe the most important benefit AM can bring from silencers into the broader small arms space is the aspect of business model innovation.Over the last two years, a great number of boutique silencer companies have been able to launch rapidly leveraging software and design skills directly into product realization with a clear marketing message and (in most cases) a competent value proposition.

Not all have been able to execute as well as others, but generally speaking, AM has really energized the silencer space into its most exciting time in history.It could feasibly do something similar for the rest of the small arms space by enabling boutique and enthusiast products that wouldn’t be feasible otherwise.On the show floor, I saw polymer additive everywhere as well.

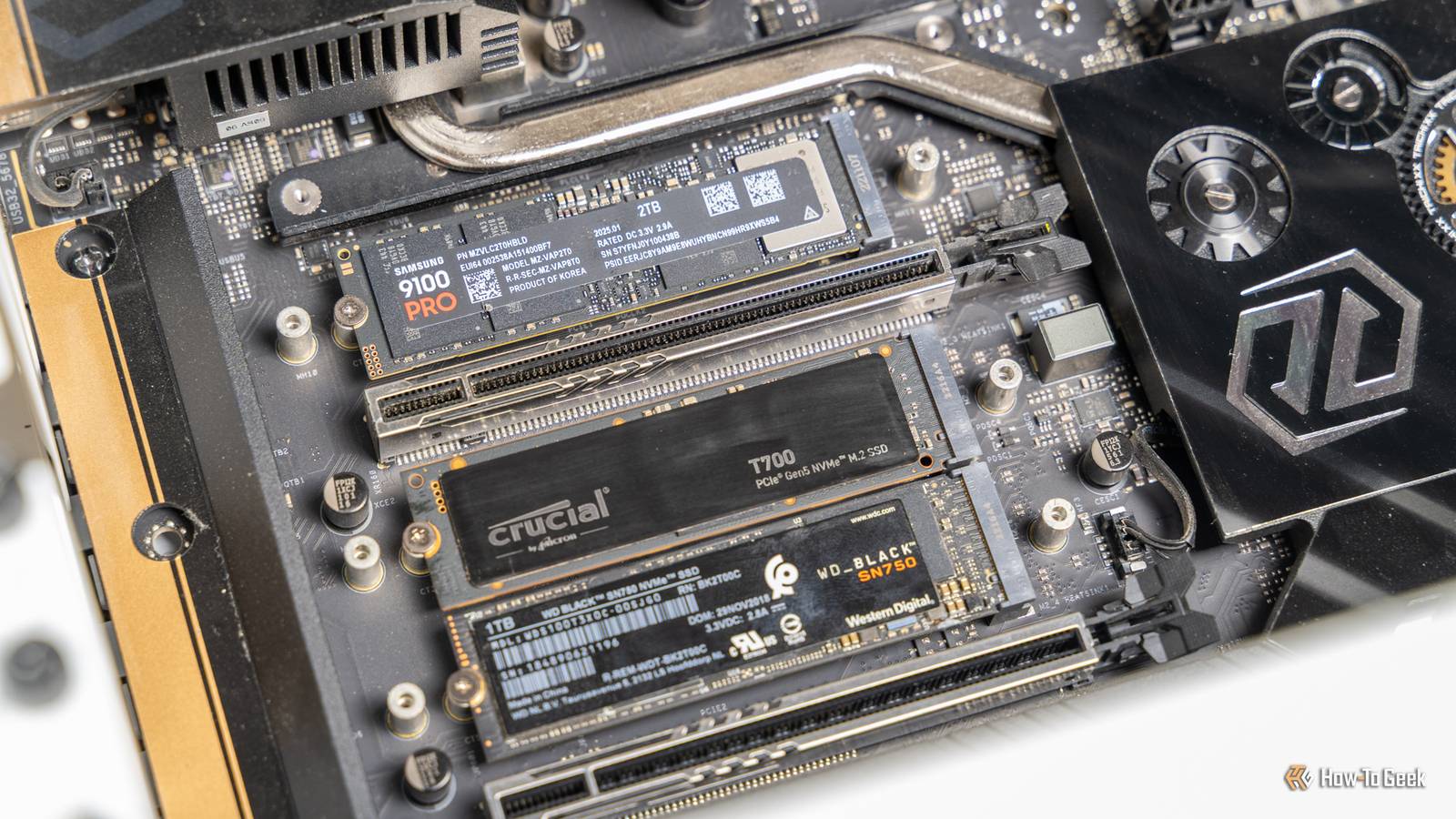

HP’s Multi Jet Fusion has been adopted as a manufacturing process for accessory items by small development companies for the last four years, printing things like housings for pressure pads, covers and anti reflection devices for electro-optics, and even entire housings for night vision goggles.In the night vision sector, we saw not just sintered buttons for controls on goggles, but even titanium printed swing arms and other metal parts.AM Silencers Rapidly Evolving with Growth, Challenges, and Solutions SHOT Show 2026 was the single biggest collection of AM silencer activity that’s ever existed, evidenced by booths from powder suppliers, AM machine companies, outsourced production partners, and providers of finishing services.

The U.S.civilian silencer market grew 31 percent in just 2025 alone, according to new data from the Bureau of Alcohol, Tobacco, Firearms and Explosives (ATF).This was even before the latest regulatory change that went into affect on January 1st, 2026, which eliminated the monetary tax associated with the application and approval process for silencer purchasing.

It has already been reported by the American Suppressor Association that on January 1st, the ATF E-Forms system processed roughly 60 times the typical daily demand for forms.We can expect close to a doubling of growth in the U.S.consumer silencer market in 2026.

Nearly 750,000 new silencers were purchased in 2025 (a 31 percent growth in total registered silencers), and with 125,000 ownership application forms processed on just the first day of 2026, it’s likely over a million will be sold this year.It doesn’t take more than walking around the SHOT Show floor to understand just what percentage of those are likely to be additively manufactured.This is the biggest growth opportunity the industry has ever experienced.

However, all that growth is not without challenges and changes.The impacts in powder demand to support this growth are significant, with huge volumes of powder now being shipped to support it.One outsourced print services provider who plays a notable role in printing silencers indicated they order 2 tons of titanium powder per month (and that doesn’t even account for the Inconel silencers they make).

However, all of this activity has rapidly deteriorated powder margins, almost out of nowhere.Powder producers are happy to have their investments in capacity now being paid for, but profitability is now difficult.New solutions in the silencer market are also being presented—an expected outcome of so much activity.

HP in particular showed off some of its metal binder jetting capabilities in the context of silencers, touting significantly lower costs per unit due to better productivity in the process.This could be welcome news to the silencer market, which will now also face significant margin pressure.Printed silencers are moving from boutique, high-value innovation on a fast track towards commodity items thanks to the explosion in demand.

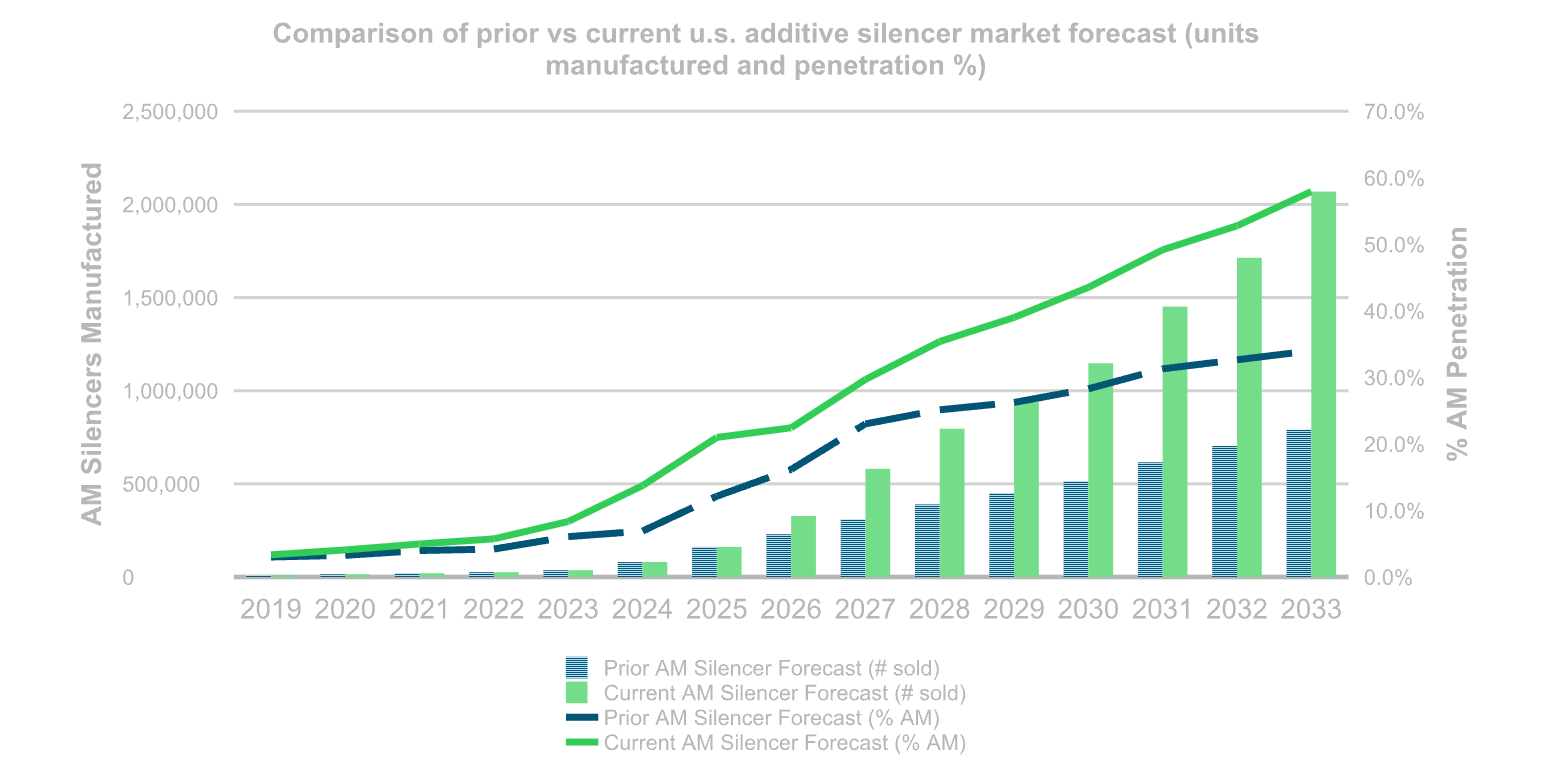

However, there are still plenty of opportunities to build a lasting brand and product in this area that stands out, even amongst the swell of new AM products in this market.Source: AM Research The Future of Advanced Powder Metal Manufacturing Technologies in Small Arms The future for both MIM and AM powder-based advanced manufacturing techniques is a bit of a mixed bag today.The overall firearms industry has been notably down the last two years, which has impacted overall demand for new firearm orders and parts and thus affected the MIM industry.

However, MIM continues to evolve in attempts to gain share of parts which might otherwise have been machined, and increases in part size and material capabilities will keep pushing MIM forward.In addition, the co-adoption of additive manufacturing technologies, including both powder bed fusion and binder jetting, alongside MIM as a one-two punch for advanced manufacturing is believed to be a net benefit for MIM.For AM technologies like powder bed fusion in both polymers and metals, and also more recently binder jetting and UV photopolymerization, there is significant growth ahead.

Most of this is concentrated in silencer manufacturing, but as pointed out in the initial section and reviewing the SHOT Show 2026 exhibition, there are clearly more applications in small arms.The AM industry needs to understand that this is being driven by the commercial market.The U.S.

military has a major role in influencing the commercial market, but the volume of parts is significantly and increasingly larger each year on the commercial side.Military contracts can be valuable, but they only represent about 3 to 5 percent of total silencers sold each year.At present, the focus of stakeholders in this area who want to expand from the increasingly crowded silencer market should focus on developing a brand to support business model innovation in this space.

That’s because the market environment is favorable for these types of enthusiast and boutique products—most of which can be served by additive manufacturing.To learn more, read the AM Research “Additive Manufacturing of Firearm Silencers: 2026 Market Update,” meant to supplement our 2024 market study.Scott Dunham is Executive Vice President of Research at AM Research.

He has authored dozens of in-depth market research studies on various aspects of the 3D printing industry, giving him one of the widest perspectives on the technology in the world.He has spoken at many prestigious events and is regularly consulted and cited by industry leading companies.At Additive Manufacturing Strategies 2026, he will present “20(/)30 Vision: Market Data” on February 24th, “Dental AM Market Forecast” on February 25th, and “Panel: 3DP/AM Market Data and Outlook” and “AM Applications Data” on February 26th.

You can register for the event here.Subscribe to Our Email Newsletter Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.Print Services Upload your 3D Models and get them printed quickly and efficiently.

Powered by FacFox Powered by 3D Systems Powered by Craftcloud Powered by Xometry 3DPrinting Business Directory 3DPrinting Business Directory

Read More